Introduction: What is a tractor pto drive shaft?

A tractor PTO drive shaft refers to the power take-off system of a tractor. It is an essential component of any farming operation as it transfers power from a tractor's engine to a wide variety of equipment used for tilling, planting, and harvesting crops. In this article, we will explore how the PTO drive shaft works and its importance in modern-day farming.

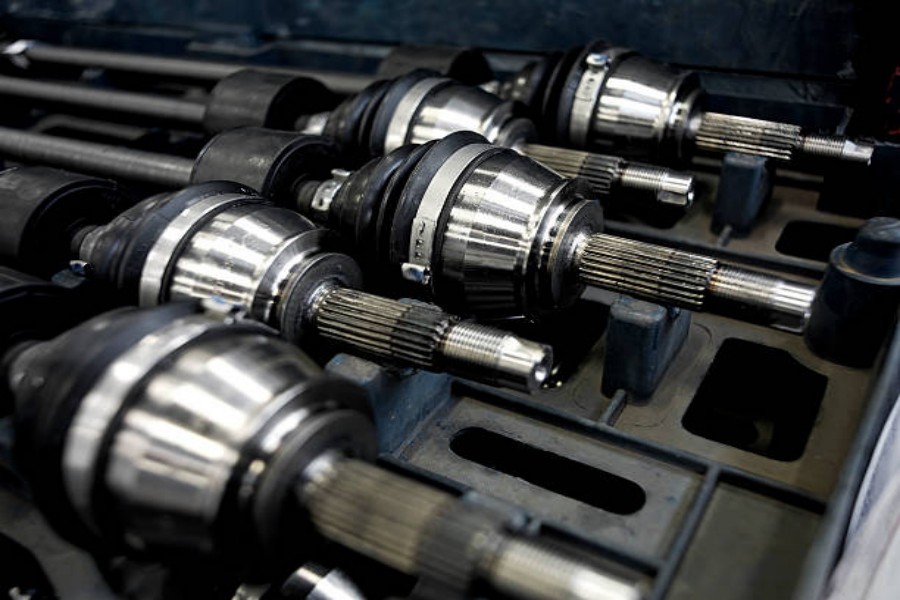

How Does a Tractor PTO Drive Shaft Work?

A tractor PTO drive shaft works by transferring power from the tractor's engine to a spinning implement. The spinning implement is connected to the PTO shaft, which is then turned by the tractor's engine. This rotation allows the implement to perform its function, such as tilling, harrowing, or planting. The PTO shaft is connected to the implement through a universal joint, which allows for flexibility in the rotation of the implement.

Types of Tractor PTO Drive Shafts

PTO drive shafts come in different types, categorized by their speed and diameter. The most common types are the 540-rpm and 1000-rpm shafts. The 540-rpm shaft operates at a relatively slow speed, making it suitable for light-duty tasks such as mowing grass. The 1000-rpm shaft, on the other hand, operates at a higher speed and is used mostly for heavy-duty tasks such as tilling and plowing. In addition to these two, there is also a third type called the 2000-rpm shaft, which is used in specialized farming applications.

Importance of a Tractor PTO Drive Shaft in Farming

A tractor PTO drive shaft is an essential component of any farming operation. As mentioned earlier, it is responsible for transferring power from the tractor's engine to various equipment used in farming. Without it, farmers would be unable to perform essential tasks such as plowing, planting, and harvesting. In addition, the PTO drive shaft also helps to increase efficiency and reduce labor costs, as it allows farmers to use a wide variety of equipment instead of relying on manual labor.

Troubleshooting Common PTO Drive Shaft Problems

Like any other machinery, PTO drive shafts can also develop problems over time. Here are some common problems and their solutions:

- Leaking oil: This could be caused by a damaged seal, and the solution is to replace the seal.

- Broken shaft: This could be caused by overloading the shaft. The solution is to replace the entire shaft.

- Noise: This could be caused by worn bearings. The solution is to replace the bearings.

- Slipping: This could be caused by a misaligned shaft or worn universal joints. The solution is to realign the shaft or replace the universal joints.

Maintenance Tips for a Tractor PTO Drive Shaft

To extend the life of your PTO drive shaft and prevent problems, regular maintenance is essential. Here are some maintenance tips:

- Inspect the shaft regularly for signs of damage or wear.

- Clean the shaft and implement after every use to prevent buildup of debris and rust.

- Grease the universal joints and bearings at least once a year.

- Replace worn-out parts as soon as possible to prevent further damage.

Buying a Tractor PTO Drive Shaft

When buying a PTO drive shaft, there are several factors to consider, including the type, size, and brand. It is important to choose a shaft that is compatible with your tractor and the equipment you plan to use it with. In addition, it is crucial to buy from a reputable dealer or manufacturer to ensure the quality and durability of the product.

Conclusion

A tractor PTO drive shaft is a critical component of farming equipment. It allows farmers to perform essential tasks such as tilling, planting, and harvesting, efficiently and cost-effectively. While it is prone to wear and tear, regular maintenance can prevent problems and extend its lifespan. When buying a PTO drive shaft, choose a reputable dealer or manufacturer to ensure quality and compatibility with your tractor and equipment.