Introduction

pto friction clutch is an essential component in a wide range of agricultural and industrial equipment. It allows the transfer of power from the engine to the attached equipment, enabling them to operate effectively. A PTO clutch is designed to engage and disengage the power transmission from the tractor engine to the gearboxes of the equipment. In this article, we will discuss the various aspects of PTO friction clutch technology and how it works.

What is a PTO Friction Clutch?

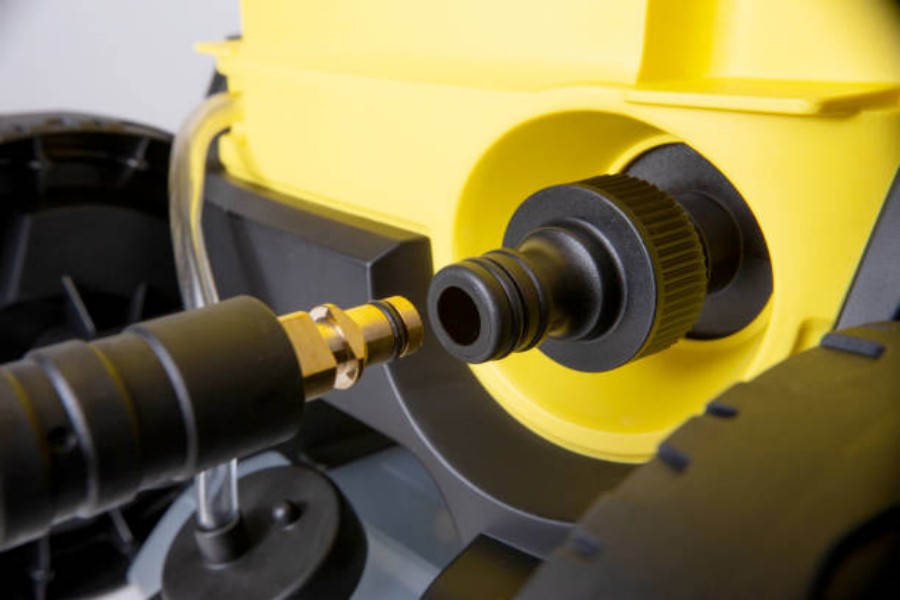

A PTO friction clutch is a mechanism that transfers power from the engine to the transmission of an attached equipment or machinery. It is essentially a clutch that is designed to engage or disengage the power transmission from the tractor engine to the equipment gearbox. Typically, a PTO clutch is mounted on the rear of the tractor and is driven by the engine.

How a PTO Friction Clutch Works?

A PTO friction clutch works by engaging or disengaging the transmission shaft from the tractor engine's power output shaft. When the PTO clutch is engaged, the power from the engine is transmitted through the clutch and then to the transmission. When the PTO clutch is disengaged, the power output from the engine is cut off, and the equipment transmission stops rotating. A PTO friction clutch operates using a set of friction plates that are coated with a special friction material. When the clutch is engaged, the friction plates clamp onto the flywheel, driving the transmission via the gearbox.

Types of PTO Clutches

There are different types of PTO clutches available, including mechanical, hydraulic, and electromagnetic PTO clutches. A mechanical PTO clutch is operated by a lever that moves the clutch assembly to engage or disengage the transmission. A hydraulic PTO clutch uses hydraulic pressure to engage or disengage the clutch. An electromagnetic PTO clutch uses an electromagnetic field to engage or disengage the transmission.

PTO Friction Clutch Maintenance

Maintenance of a PTO friction clutch is essential for its longevity and reliable operation. Keeping the clutch clean and well-lubricated is crucial to avoid any damages and premature failure. The clutch should be regularly inspected and the worn or damaged friction plates should be replaced immediately. It is also essential to adjust the clutch gap regularly to ensure smooth operation.

Benefits of PTO Friction Clutch Technology

PTO friction clutch technology offers several advantages, including superior power transfer from the engine, reduced energy waste, and fuel economy. PTO clutches are designed to be efficient, reliable, and easy to operate. They are widely used in agriculture, construction, and many other industrial applications.

Key Applications of PTO Friction Clutch

PTO friction clutches are used in various applications, including farm machinery, construction equipment, and industrial machinery. In farm machinery, PTO clutches are used in tractors, harvesters, balers, and other equipment. In construction equipment, PTO clutches are used in excavators, loaders, and bulldozers. In industrial machinery, PTO clutches are used in pumps, compressors, generators, and other equipment.

PTO Friction Clutch Safety Precautions

Safety precautions should be taken when operating PTO friction clutches. Before engaging or disengaging the clutch, operators should make sure that the attached equipment is clear of any obstacles or persons. It is also essential to follow the manufacturer's recommendations concerning the proper use and maintenance of the PTO clutch to ensure safe and reliable operation.

The Future of PTO Friction Clutch Technology

The future of PTO friction clutch technology is focused on improving efficiency, durability, and ease of use. There are ongoing efforts to develop more advanced and innovative PTO clutches that are more efficient, reliable, and easier to operate. Future PTO clutches are likely to incorporate more advanced materials and technologies to achieve these goals.

Conclusion

PTO friction clutches are an essential component in agricultural and industrial equipment. They are designed to allow the transfer of power from the engine to the attached equipment to operate effectively. Understanding the functionality and maintenance of PTO clutches is crucial for efficient and reliable operation. The development of more advanced and innovative PTO clutch technology is focused on achieving greater efficiency, durability, and ease of use.